Harness the power of the SUN

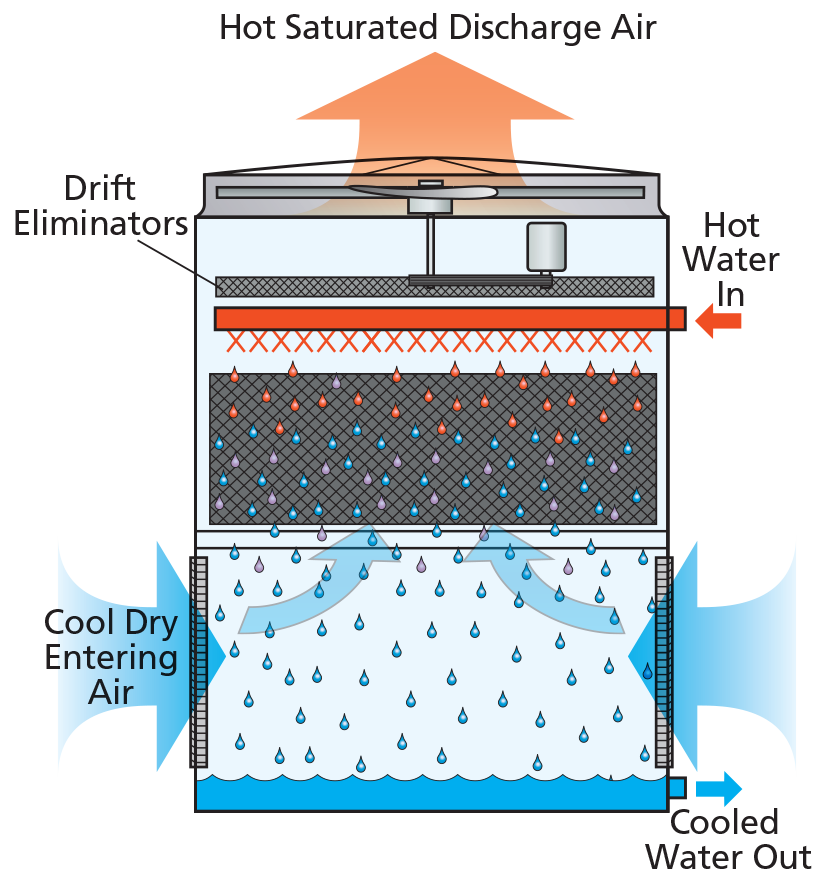

EVAPCO, Inc. continues its dedication to energy efficiency improvements with the newest AT Series induced draft, counterflow cooling tower – the EVAPCO SUN. Crafted from decades of engineering know-how, the SUN cooling towers series from EVAPCO features state-of-the-art induced draft, counterflow technology to deliver superior operating advantages in any climate. From performance to maintenance, they simply work smarter.