Read the original here.

Introduction

Operator training has become one of the most prevalent areas of deficiency in Process Safety Management (PSM)Programs for refrigeration systems today. High turnover in the refrigeration industry coupled with high complexity system designs and an increasing void of technicians trained in foundational trades are the perfect storm for compliance challenges among operators of large refrigeration systems today. In recent years, the average service tenure for ammonia technicians operating refrigeration systems has dropped. In many facilities today, it is common to find most of the operations personnel running refrigeration systems with fewer than 5 years of service. (Based on informal polling of a small group of large ammonia system operators). It is not difficult to provide training to develop an ammonia technician, but as the systems become more complex, it takes more time. The advent of low charge packaged refrigeration systems has created an opportunity to ensure higher safety performance and compliance with training requirements, due to the replication nature of these systems and the documentation available with them. Facilities using multiple machinery rooms and numerous temperature ranges in the past are now able to use independent packaged ammonia systems to maintain low-charges of ammonia thereby decreasing the risk in the event of an ammonia release,enhancing the efficiency of training offered and making regulatory compliance easier.

Overview of Low Charge Ammonia Systems

Background:

Low Charge Packaged Refrigeration Systems are growing in popularity so understanding this new technology, and how it is applied, is an important part of understanding the operational benefits and how they could be safer to operate. Low Charge Packaged Systems are best located locally near the cooling load. Multiple packaged units can be spread throughout a facility and located close to the cooling loads, in contrast with central systems that have central machinery room(s)serving many cooling loads and piped to the various areas throughout a facility with long-run ammonia pipe headers. The low ammonia charge is primarily achieved due to the elimination of the ammonia piping that runs to and from the central machinery room, and its associated large pressure vessels inherent in a central machinery room.

Low Charge Packaged Systems are also typically factory assembled and tested, which can facilitate faster installation and start-ups for refrigerated facilities. Each package is typically provided with the evaporator,compressor,vessels and condenser all pre-assembled,wired and ready for a single point electrical connection on site.

The driving force behind these packaged low charge systems is the increasing enforcement and burden of government regulations (primarily OSHA and EPA), as well as growing industry codes and standards. These regulations and codes often reference a Threshold Quantity (TQ) related to total refrigerant charge in a process. An example of this is the 10,000 lb. ammonia TQ under OSHA’s Process Safety Management (PSM) program and EPA’s Risk Management Plan (RMP). Minimizing the total system charge, to stay below a TQ, is now a key objective for many owners and operators, who are evaluating the refrigeration system design for new warehouse and food processing facilities. The Low Charge Packaged Systems represent a new technology and new overall system design that help solve this need and result in safer systems due to the significantly lower charge.

The growing use of Low Charge Packaged Systems is also driven by industry’s response to the environmental and safety issues surrounding both synthetic refrigerants (HCFC, HFC’s & HFO’s) and natural refrigerants (Ammonia, CO2 & hydrocarbons). Navigating these environmental and safety issues to determine what refrigerant a facility should use can be made easier with a low charge ammonia packaged systems because there is much less ammonia to worry about and using ammonia is a great solution for many applications due to its superior energy efficiency, system reliability and low operating costs.

Applications:

Industrial refrigeration projects range from small to large, and from new “greenfield” projects to various expansions or retrofit projects of existing facilities. Low Charge Packaged Ammonia Systems can fit many different project types. An important step to implementing this new technology is for the owner’s design team, and/or design build contractor,to integrate the design attributes of the packaged solution into the early stages of the building design development process. This can maximize the potential cost savings for using this solution because it can eliminate the cost of a machinery room from your building budget, minimize any extra steel cost impact and also result in a lower electrical installation budget.

Another potential application for this technology is implementing a“Hybrid Design” using a combination of packaged units along with a smaller conventional field erected system, serving different parts of a facility. For example: In a warehouse expansion you could manage a freezer/dock expansion through utilization of the existing high-temp system for the dock while the freezer would be managed with the independent packaged unit concept. The above scenario could eliminate the need to expand or add to the traditional machinery room.

Low Charge Packaged Systems are available in different configurations. Understanding how they can be applied to varying needs is critical. Different configurations could include:

- Direct cooling of the space with ammonia in the evaporator (Direct System). Evaporators are typically located in a Penthouse and close coupled to the rest of the packaged system.

- Indirect cooling of the space or process with a secondary fluid in the cooling coil or heat exchanger (Indirect System). This design is also called a chiller. The secondary fluid is cooled in the chiller, or multiple chillers, and pumped to remote cooling coils, which can be ceiling hung or in a penthouse. The chilled secondary fluid can also feed various types of process loads. The secondary fluid can be various fluids such as water, propylene glycol, calcium chloride, aqueous ammonia, CO2 volatile brine, etc.

Design Considerations:

- Packaged Equipment Sizing and Layout: Applying Low Charge Packaged Systems is similar to the initial steps of applying any other refrigeration systems. You start with calculating the cooling load for each room or process,then select the equipment that meets the load and facilitates good air distribution or cooling for the process.

Once the cooling loads are estimated for each room, the Low Charge Packaged System equipment layout can be determined. This involves deciding how many packaged units are required for each room and how best to locate them. Similar to a penthouse configuration, the key is locating the equipment such that the air can be evenly distributed throughout the facility. - Accessibility: Since many Low Charge Packaged Systems are installed near the room cooling load they often are required to be installed on the roof above the room. Therefore access to the roof for maintenance and service of the packaged units is an important consideration.

The accessibility to packaged units must be considered in the building design. If the unit is located near the roof edge,you should consult local, state and federal codes, standards and OSHA requirements, which may dictate railings or other safety criteria.

For facilities that have multiple units on the roof, stairs or a stair tower should be provided to access the roof instead of a ladder, in order to facilitate easy and safe maintenance access. A stair tower also provides a good structural location to install a small davit or jib crane that can be used to raise and lower the larger components from packaged units to and from the roof to the ground. This will be beneficial during any significant repair activities including, but not limited to replacing a motor.

Compressor or motor removal and replacement is the biggest concern with the roof top packaged units. To facilitate this, most packages have a trolley and monorail to provide easy removal of the compressor or motor from the package. Once the item is removed from the package a cart with balloon tires can transport it across the roof, where is can be lifted to the ground with a roof mounted davit, boom truck or a small crane.

Reduction of Ammonia Charge & Safer System Operation:

As regulatory inspectors become more familiar with the refrigeration industry, regulatory enforcement is of greater concern to many refrigeration system owner/operators. A key benefit is that Low Charge Packaged Ammonia Systems arguably offer inherently safer technology and a potential reduction in the regulatory burden to owners and operators since they have the following attributes:

- Contain significantly less ammonia and are safer to operate, maintain & work around

- Allow owners to stay below 10,000 lb Threshold Quantity set by OSHA’s PSM and EPA’s RMP regulations

- Reduced off-site consequences in the event of an ammonia release

- Reduce the liability & exposure to fines

- Manufacturers can provide the operating procedures, maintenance procedures, product hazard review, tagging, labeling & signage required for the packages

- Package manufacturers must comply with applicable code and standards

All of the above lowers the owner’s regulatory compliance costs. In fact, because of these attributes and the availability of documentation, low charge ammonia packages allow an owner to easily implement IIAR’s Ammonia Resource Management (ARM) program. The ARM program is available to help owners comply with OSHA’s and EPA’s General Duty Clause, which all facilities with less than 10,000 lb of ammonia must comply with. The ARM program provides guidelines that an owner should follow in order to satisfy the requirements of the General Duty Clause, and the new low charge ammonia packages available in the market should provide much of the features and documentation called for in the ARM program, making compliance easier.

Training Attributes & Benefits:

Operator training is a must-have element for any size refrigeration system or program. There is no replacement for emergency preparedness, training, personal protective equipment and familiarization with system operations because small amounts of ammonia under the right conditions and lack of PPE could be harmful. Size of the system and the ammonia charge must not cause someone to take for granted the risks posed by ammonia and the personal protective equipment required to be worn when working around it. Training should be accomplished on low-charge packaged systems just like conventional ammonia refrigeration systems. The major difference is that each of the packaged systems (at least those designed by the same manufacturer), will follow similar design, documentation, operations and maintenance procedures. The time required to train someone on operations and maintenance for these systems is less due to process simplification. This is obviously based on the assumption that if several systems were used they would have a standardized design. Their compact nature and simplified design allow for easier review of operating and maintenance procedures. Just like similar equipment in conventional systems, a user with multiple like units, would not need to repeat training for each package since they would operate the same way. Operators of low-charge systems are able to take four easy steps to ensure readiness around these systems.

- Ensure ammonia awareness and understanding of ammonia chemical & physical properties and how and when to properly use PPE

- Understand the fundamentals of ammonia refrigeration and the process design of the low-charge package being used

- Ensure familiarization with process documentation provided with the equipment by the OEM

- Understanding of facility emergency procedures and coordination of those procedures with off-site emergency responders

Training is easier with low charge packages systems because:

- The operational hazards for an owner are identified earlier through the manufacturer’s product testing, development and improvement

- Every system is NOT different for a particular manufacturer as is the case with traditional systems

- Documentation consistency due to standard packaged system design

- Pre-engineered & manufactured systems are simpler to operate than custom built field erected ammonia refrigeration systems

Documentation and Testing:

The low charge packaged systems typically have excellent & complete documentation available from the manufacturer. Standardized documentation is often more readily available than for field erected systems since it is pre-developed. Examples of this include:

Product Application and Engineering Manuals

Rigging & Handling Manuals

Installation Operation & Maintenance Manuals

Hazard Reviews often can be provided to the owner to assist with their onsite safety programs and PSM program if applicable

All Operating Procedures that Process Safety Management calls for should be available from the manufacturer (even though PSM may not be applicable)

Preventative Maintenance procedures should be available from the manufacturer for the product to assist the owner & operator

All of the above can significantly help reduce the regulatory burden on the owner and contractor. A sample of this documentation is provided below. In addition, the supplier of the packaged system should enforce strict quality control program for the manufacturing of the units and thoroughly inspect and test them prior to shipment to guarantee quality and trouble free operation. This allows for one of the best features of the low charge packaged units to become a reality, and that is a quick, easy and safe startup. This benefit can be a reality if the following factory testing is performed on the packaged systems:

- Factory Acceptance Test (FAT), electrical loop checks and control simulations

- Motor rotations are verified

- Inspection for internal cleanliness

- System pressure test and Leak test

- Vacuum dehydration test to 500 microns

- Delivery of the unit with a 15 lb nitrogen blanket charge assuring the end-user of internal system cleanliness

- The installing contractor then only needs to pull the nitrogen out and pull a vacuum to 2000 microns before charging with ammonia

In addition, detailed installation instructions should be provided the by the package manufacturer along with concise, consistent and repeatable operating & maintenance procedures.This allows for a very effective hand off from the manufacturer to the installing contractor and end-user.

OEM engineers, builders and operators are able to design, build, evaluate and tweak the systems and documentation prior to delivery to the customer allowing a top-down vetting process to minimize hassle on the part of the consumer. The operations and maintenance procedures will be written and validated prior to delivery to the customer. Production of standardized packaged system models allow for and ensure consistency and easy implementation in the production environment.

Operation and Maintenance:

One of the most powerful attributes of the packaged low charge ammonia systems is the ability of the manufacturer to provide complete Operating Procedures and Maintenance Procedures for the units. This documentation can meet the requirements of Process Safety Management even though the units may not need to due to the very low charge. Pre-engineered and manufactured packaged systems can also be simpler to operate and maintain than custom built field erected ammonia refrigeration systems. They are often designed with significant features to facilitate easy maintenance by the inclusion of such things as:

- Evaporator penthouse access doors& fan/motor removal davits

- Exterior Service Panel on machinery room including the ability to connect a pump-out unit

- Monorail and hoist for compressor or motor removal•“Walk-in” machinery room with required maintenance access for all components

- Maintenance is performed indoors on the roof instead of outdoors

- Stainless steel piping, eliminating pipe corrosion

- Isolation valves on major equipment

- Cable tray for wiring for easy access

How Does It Compare To Traditional Ammonia Systems?

Traditional ammonia refrigeration systems

are typically fully customized based upon the specific project. The nature of unique designs typically require Process Hazard Analyses (PHA) to be performed to identify problems during the design phase of a project. All too often, I find that the PHA falls short of identifying all of the relevant hazards. This could be the result of a host of unrelated issues, but a few include the fact that many design changes to systems in food manufacturing occur on the fly and as a result of a customer change or product requirement. These situations are usually time sensitive, meaning that with little design time or planning ability, the system has to be designed, installed and operating. The short-fused approach to these changes leaves a lot to be desired and one could argue that many are not fully compliant at start-up for all of the reasons already mentioned. To illustrate this, let’s pose a few questions for you to ponder:

- Were all of the right people (the operators/technicians) present and included in the design discussions for the changes?

- Did the operators/technicians have the opportunity to participate in the PHA?

- Did the operators/technicians have the opportunity to provide input on equipment placement, controls or methods for accessing equipment?

- Were the operators/technicians trained in the new equipment?

- Have the operating procedures been written and validated?

- Has the system been labeled and tagged to match the procedures and P&IDs?

I ask the last question, because many would argue that the most dangerous time is during startup of a new or modified system. If the system is not labeled and tagged correctly and consistently between documents, then you might fall short of the preparedness needed in the event of an emergency. These are merely a few of the items that help ensure safety and compliance at startup. The low charge concept allows for a simple hazard review that in most cases might be boilerplate in nature and just involve a briefing of operations personnel to ensure awareness, understanding and to simply identify if any other concerns might exist for this type of system being used at the location.

While the hassles of ensuring compliance with Process Safety Information documentation is the responsibility of the owner/operator, the collection and preparation of the Process Safety Information is shared by the provider of the equipment. Items such as ventilation system design, electrical classification and ammonia detection, inventory calculations and others are all part of the OEM documentation package created when systems are fully built off-site and provided with the package. The typical requirements for having these documents may be negated by the fact that low-charge systems in most cases would not be subject to PSM and RMP requirements, given their individual process ammonia inventories would be less than 10,000 pounds. Keep in mind, however that General Duty requirements always apply, so the provision of this documentation by your OEM equipment provider will support you by providing the foundation for your training efforts. You must, however acquaint yourself with the information and ensure that training for all of your operator/technicians on the operating procedures is completed. Training is not an option. Training MUST be paired with this technology to capture the safety benefits of this solution. The owner/operator must appreciate the regulatory advantages of low charge packaged systems, but respect that all of the foundational elements are still necessary to ensure operational and personnel safety and compliance with General Duty requirements. As outlined on page 6, IIAR’s ARM program provides the necessary guidelines to comply with the General Duty Clause and how low charge ammonia packages make this easier.

Other Related Facility Impacts

Personal protective equipment (PPE):The PPE required for operations and maintenance of low-charge packaged systems in no different than conventional systems. The key isfull skin coverage and respiratory protection. The selection of equipment to be worn by the ammonia operator/technician will vary based on the tasks being performed. For example, an operator/technician performing rounds and visual inspections would simply wear a standard work uniform with long sleeves, safety glasses, hard hat, hearing protection and abrasion resistant gloves. Whereas an operator/technician performing oil draining would add the apron, neoprene gloves, APR, and protective hood to the ensemble. Each facility owner may vary slightly in their choice of protective equipment, but a listing of standard protection for refrigeration operators/technicians is as follows:

- Long sleeved shirt

- Safety glasses/goggles

- Work gloves (abrasion resistant)

- Safety Boots (comply with ASTM F2413 standard)

- Hard Hat

- Hearing protection

- Full face air purifying respirator (APR) with ammonia cartridges

- Neoprene insulated gloves

- Ammonia/chemical splash resistant apron

- Protective hood (fire resistant style to be worn over APR)

Safety shower & eye wash: Safety shower/eye wash stations are still required for low-charge packaged systems and need to satisfy the requirements of inside and outside of the machinery room along with temperature controls to prevent the overheating or freezing of decontamination water. They may or may not be included with the low charge packaged unit so it is important that the installing contractor and owner determine what is needed for a particular project.

Emergency response:Training preparation for emergencies and coordination with emergency responders is measurably easier with packaged low-charge systems. Emergencies can be managed through design in many cases where monitored alarms summon responders much like fire alarms or home security systems summon fire or police. Additionally, the ventilation system could be designed to contain and/or divert ammonia vapor to control systems such as scrubbers or flares intended to neutralize ammonia vapor. In addition, the manufacturer of the packaged system can provide predetermined emergency shutdown procedures for the low charge units, which are documented and easy to train operators on.

Off-site consequences: Low-charge ammonia by its nature is of less consequence to public receptors off-site. Having less ammonia means that if it leaks, it doesn’t go as far and it impacts fewer people. While the risks to operators working directly with ammonia (such as valve or component service remain similar, there is a unique difference with low-charge ammonia packaged systems as compared to other reduced inventory scenarios. With the introduction of the PSM and RMP rules in the 90’s, it was the clever idea of many chemical packagers to simply reduce the amount of chemical in containers. A one-ton container of chlorine, for example may have been limited to 1,350 pounds. The overall consequence of the container failure would indeed be reduced since the amount of available chlorine was less. In reality, however the users of chlorine did not change their needs. This created an increase in the frequency by which deliveries were needed and increased the number of connections and disconnections of the piping to utilize the chlorine. The increased transportation, handling and connection/disconnections arguably increased the risk to the public and the operations personnel working in this environment. Ammonia systems are different. Since it is a closed-loop system, we don’t need to add any ammonia unless it leaks out. Yes, we can agree that we lose ammonia to the air when we drain oil, change valves, etc... but it is not routine that we add ammonia like would be typical of other chemical processes. The low-charge packed ammonia systems are safer by design. Since the systems are independent, you could argue that there is little ifany increased risk of using multiple systems.

Reduction in Liability & Exposure to Fines:

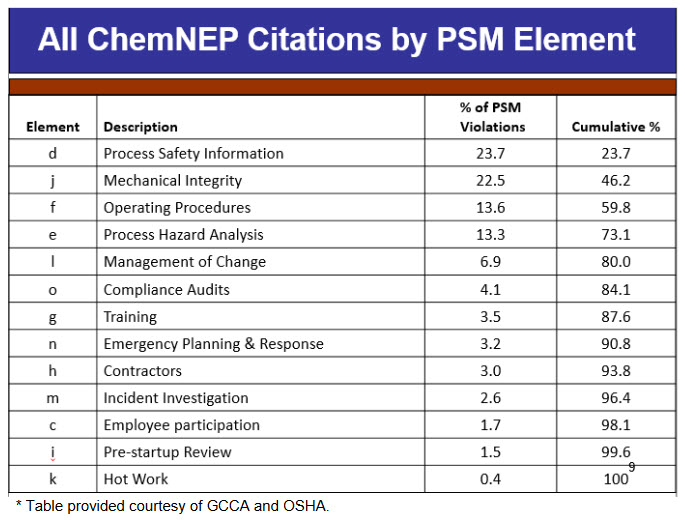

The table below*lists the major categories where citations have been issued by OSHA over the last 3 years for PSM violations. The top 4 categories, which comprise 73.1% of all the PSM citations,are Process Safety Information, Mechanical Integrity, Operating Procedures and Process Hazard Analysis.As outlined herein, packaged low charge ammonia systems provide many features, attributes and documentation that will satisfy the requirements and criteria for these PSM elements and as a result will significantly reduce an owner’s liability related to these elements (along with others) and reduce their exposure to fines for noncompliance.

Lower Cost of Ownership

Packaged low charge ammonia systems can provide a lower cost of ownership than traditional systems due to several factors including:

- Lower building costs through the elimination or reduction in size of a central machineryroom

- Lower electric bills due to the elimination of pressure/temperature drops associated with long runs of ammonia field piping in central plants

- Lower refrigerant costs due to significantly lower refrigerant quantities•Lower regulatory & compliance costs as highlighted in this paper

- Clearly defined and easy to use Installation, Operation & Maintenance procedures as highlighted in this paper

- Consistent packaged system designs and documentation simplifies training and unit operation as highlighted in this paper

Summary & Conclusion

Technology is what drives improvements in all aspects of our world. Out of the box thinking makes us better at what we do. Low charge packaged ammonia systems are simply a new way of applying ammonia refrigeration in a more economical, functional and safer manner to achieve the same end results. This new technology is overdue in the industrial refrigeration industry and its entrance into the market resembles the evolution of packaged HVAC equipment that occurred decades ago and brought many benefits and advantages to contractors, end-users, owners and consumers because of its technological improvements. This new technology makes ammonia refrigeration easier to use and implement. It helps solves many challenges related to safety, training, regulatory compliance, energy efficiency, project execution and provides a lower cost of ownership.

The refrigeration industry is dealing with its greatest challenge to date and it’s the development of skilled and qualified ammonia refrigeration operator/technicians.The push for everyone to have a four-year degree has created a void of personnel qualified in skilled trades. The number of available ammonia refrigeration jobs dwarfs the number of qualified operator/technicians available. Utilizing low charge packaged ammonia systems does not eliminate the need for operator training, it simply makes the process of training operator/technicians easier and when combined with the operational and compliance benefits of these packaged systems, produces a powerful and safer solution for owners and operators.