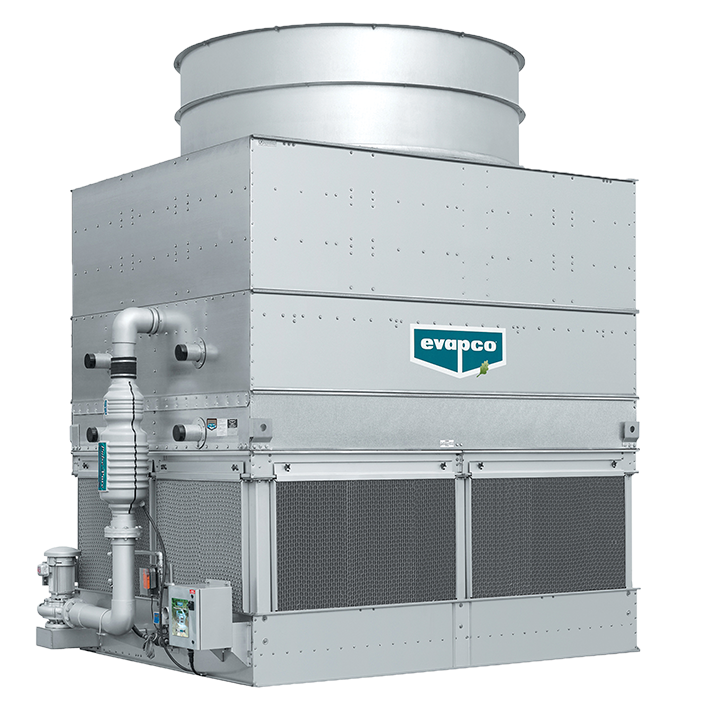

Condensers - Evaporative

A vital part of any industrial refrigeration system

Equipped with the groundbreaking CrossCool™ Internal Tube Enhancement, EVAPCO’s condensers are more efficient, easier to maintain, and easier to operate than competitor products. See how these options can fit into your application with EVAPCO's collection of BIM files.

Experience the increase in efficiency and capacity made possible by EVAPCO's patented Thermal Pak II® coil, designed to maximize heat exchange efficiency.

- BodyThe eco-PMRC offers the same features and benefits of the PMC line of evaporative condensers but utilizes EVAPCO's patented ellipti-fin coil technology to offer water savings benefits through expanded dry operation.

- BodyForced draft, axial fan models can reduce power requirements by up to 50% over centrifugal fan models of similar capacity. The PMRC Condenser has more capacity than any other forced draft condenser on the market and provides more choices due to its greater number of plan areas.

- BodyInduced draft counterflow evaporative condensers featuring signature AT features utilizes EVAPCO's patented ellipti-fin coil technology to offer water savings benefits through expanded dry operation. 122-3846 nominal tons

- Body

Induced draft, counterflow condensers featuring the patented, high efficiency EVAPCO Ellipti-fin® Coil and EVAPCO’s ARID fin Pak® dry coil. The ultimate in wet/dry performance, every model has been engineered to provide a minimum 50% of the design heat of rejection (MBH) at 60F ambient dry bulb temperature or higher, based on a 96.3F (35.7C) condensing temperature.

- BodyInduced draft counterflow condensers comprised of 181 models ranging in size from 50 to 3714 nominal tons (215 kW to 15,999 kW) designed especially for easy maintenance and long, trouble-free operation.

- Body

The Parallel Hybrid Condenser, PHC-E combines high efficiency PVC crossflow fill with EVAPCO's latest coil technology for superior induced draft, parallel flow, hybrid condenser performance.

- Body

Low noise, low height, forced draft, centrifugal fan design evaporative condenser with a capacity range of 25 to 379 nominal tons (107 to 1633 kW).

- Body

Forced draft centrifugal fan condensers are very quiet and ideal for applications where noise is a concern.