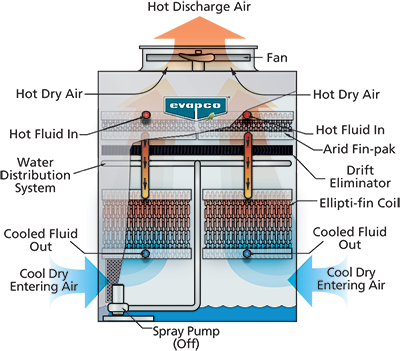

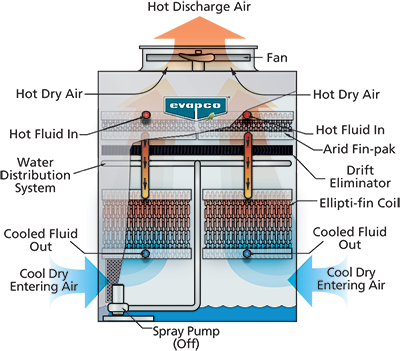

Dry Mode

- The unit maintains dry mode operation until the temperature set point can no longer be met

- While in dry mode, no water is used, thus plume is eliminated

- Dry mode operation can save thousands in water usage and sewage costs annually

In dry mode, process fluid enters the ARID fin Pak® coil through the top coil connections, the fan activates, drawing air upward through the louvers and across the coils. As the air passes over the coil, a portion of the load is dissipated to the atmosphere through the tube walls and fins through sensible heat transfer. The warm process fluid exits the ARID fin Pak coil, entering the Ellipti-fin coil through the factory installed piping; the remaining load dissipates through the tube and extended surface fins of the Ellipti-fin coil through sensible heat transfer.

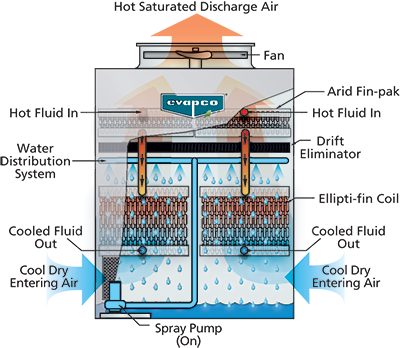

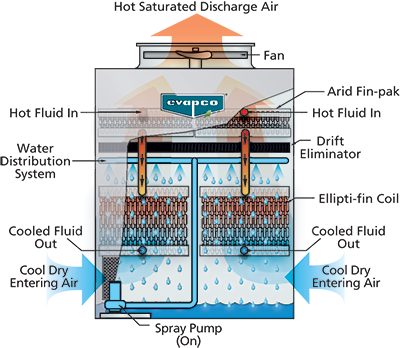

Evaporative Mode

- Once the temperature set point can no longer be met, the unit switches to evaporative mode

- The evaporative mode utilizes evaporative and dry cooling simultaneously to significantly increase cooling capacity

- The ARID fin Pak coil reduces water loss and plume by heating saturated discharge air as it leaves the unit

Process fluid enters the ARID fin Pak coil through the top coil connections, the fan and pump motors activate. As the air passes over the ARID fin Pak coil, a portion of the load dissipates to the atmosphere through the tube walls and fins through sensible heat transfer. The warm process fluid transfers to the Ellipti-fin® coil, where the spray system cascades water over the tubes of the Ellipti-fin coil, transferring heat to the water. Air is drawn upward and over the coils by the axial fan, agitating the falling water and increasing the transfer of heat. A small amount of the recirculating water evaporates due to latent heat transfer through the tube and fin walls of the Ellipti-fin coil.