Environmentally Conscious Operation ATWB

The eco-ATWB dramatically reduces water and energy consumption by increasing the unit's efficiency in both the evaporative and dry cooling modes of operation.

The eco-ATWB’s Ellipti-fin® Cooling Coil now features CrossCool™ Internal Tube Enhancement, increasing the internal heat transfer coefficient of the coil and thus the cooling capacity of the unit. The eco-ATWB offers the most models and box sizes in the industry and is designed with IBC Compliant Construction and CTI Certified Performance.

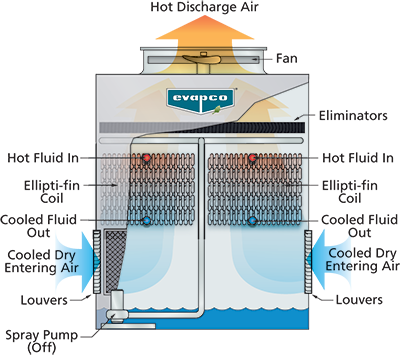

In dry mode, the recirculating spray pump is deenergized (Fan on, Pump off). The process fluid enters the eco-ATWB cooler through the top coil connection and circulates through the finned coil with the fan energized. Heat from the process fluid dissipates to the atmosphere by sensible heat transfer through the tube wall and fins to the air passing over the coils. The coils are finned to promote optimal airflow over the coil, and to maximize heat transfer area. Air is drawn over the finned coil by the fan drive system. The cooled fluid then returns to the process via the bottom coil connection. The unit will remain in the dry mode of operation until the temperature set point can no longer be met. In this mode, NO water is used and plume is eliminated.

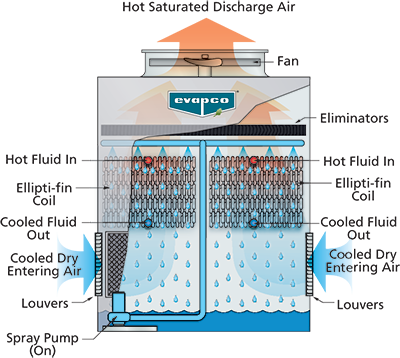

In dry mode, the recirculating spray pump is deenergized (Fan on, Pump off). The process fluid enters the eco-ATWB cooler through the top coil connection and circulates through the finned coil with the fan energized. Heat from the process fluid dissipates to the atmosphere by sensible heat transfer through the tube wall and fins to the air passing over the coils. The coils are finned to promote optimal airflow over the coil, and to maximize heat transfer area. Air is drawn over the finned coil by the fan drive system. The cooled fluid then returns to the process via the bottom coil connection. The unit will remain in the dry mode of operation until the temperature set point can no longer be met. In this mode, NO water is used and plume is eliminated. In evaporative mode, the process fluid enters the Ellipti-fin coil through the top coil connection and circulates through the finned coils. The water distribution system cascades water over the tubes of the Ellipti-fin coil, transferring heat to the water. Air is drawn upward and over the coils by the axial fan, agitating the falling water and increasing the transfer of heat. A small amount of the recirculating water evaporates due to latent heat transfer through the tube and fin walls of the Ellipti-fin coil, removing heat from the system. The cooled fluid then returns to the process via the bottom coil connection. This mode of operation provides fan energy savings due to enhanced evaporative performance and lower leaving water temperatures by utilizing evaporative cooling.

In evaporative mode, the process fluid enters the Ellipti-fin coil through the top coil connection and circulates through the finned coils. The water distribution system cascades water over the tubes of the Ellipti-fin coil, transferring heat to the water. Air is drawn upward and over the coils by the axial fan, agitating the falling water and increasing the transfer of heat. A small amount of the recirculating water evaporates due to latent heat transfer through the tube and fin walls of the Ellipti-fin coil, removing heat from the system. The cooled fluid then returns to the process via the bottom coil connection. This mode of operation provides fan energy savings due to enhanced evaporative performance and lower leaving water temperatures by utilizing evaporative cooling.