News

Mayo 14, 2018

To better serve the ever evolving needs of their customers, New England BioLabs, Inc. (NEB) recently completed the construction of a 40,000-sq-ft clean room production facility in Rowley, MA. Accurate and robust temperature control of the equipment and environment is critical to the success of the tightly controlled manufacturing processes. A key component of the cooling system that meets the stringent cooling needs at NEB’s facility is its fluid cooler, a 1.6 million BToU closed circuit cooling tower designed to provide cooling to process water for a wide variety of sophisticated plant

Abril 30, 2018

Chris Nagle, vice president of water systems at EVAPCO, was recently interviewed on the podcast, Scaling UP! During this discussion, Chris shares some of the fascinating things EVAPCO are doing to help solve this issue and provides some great advice for water treaters on how to prevent and manage white rust. He has a unique perspective and a wealth of insight on the topic of white rust and today, he explains the process of galvanizing and passivation and the challenges white rust has placed on the industry today. Take a listen to the podcast for water treaters, by water treaters.

Abril 17, 2018

Around the globe, both businesses and individuals are looking at how they can conserve water. Recognizing the importance of water conservation–and to comply with new legislation–manufacturers are focusing on products that help reduce water usage. Southern PHC magazine recently published an article that focuses on this need and what companies, like EVAPCO, are doing to help meet this demand. Read Conservation Connection to learn more.

Abril 4, 2018

At the recent Cooling Technology Institute (CTI) Annual Conference, EVAPCO's Jean-Pierre Libert presented the CTI Technical Paper titled Cooling Equipment Sound Measurements, which was very well received. The paper was recognized as a valuable contribution toward the objective of improving ATC-128 and the on-going development of the sound certification program. In addition to Libert, contributors include: Jennifer Hamilton, Scott Nevins, Will Nuckolls and Andrew Carl. This study dives into CTI's ATC-128, Europe's ISO-3744 and China's GB/T 7190 - the test codes that describe methods to measure

Marzo 19, 2018

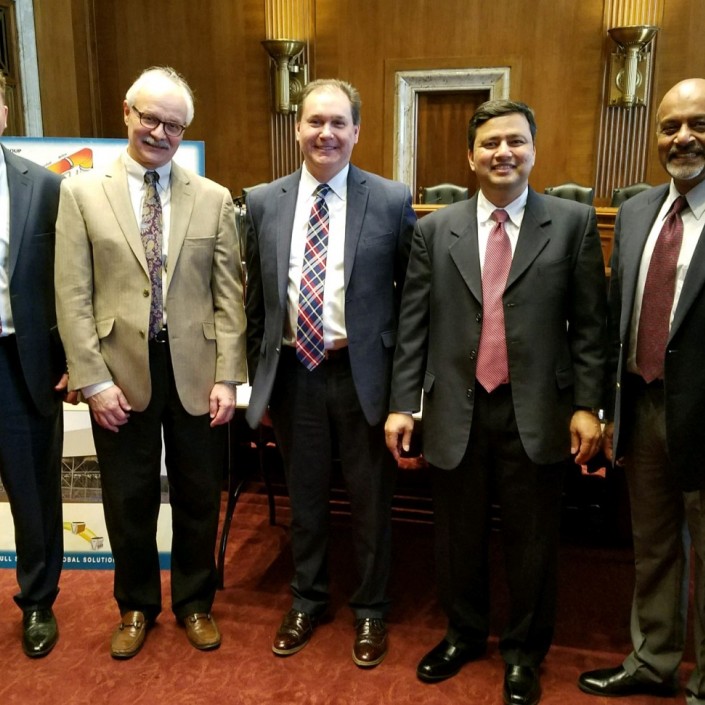

EVAPCO was selected to attend the 2018 ARPA-E Congressional Showcase that took place March 12 in the Dirksen Senate Building on Capitol Hill. ARPA-E, or Advanced Research Projects Agency-Energy, is a United States government agency tasked with promoting and funding research and development of advanced energy technologies. It is modeled after the Defense Advanced Research Projects Agency. EVAPCO partnered with the University of Cincinnati to present our “Enhanced Air-Cooling System with Optimized Asynchronously-Cooled Thermal Energy Storage.” Top research teams were selected by ARPA-E and

Marzo 16, 2018

Check out this awesome video shot at the AHR Expo conference in Chicago from Southern PHC Magazine. Learn about our dry and adiabatic closed circuit cooler from Chad Nagle, vice president of HVAC Sales and Marketing.

Marzo 15, 2018

Please read the below letter from EVAPCO President/CEO Bill Bartley: These are the times that try my soul! Two unusual and significant cost increasing events pertaining to Evapco’s North American business are currently unfolding. Consequently, this correspondence is provided to notify you that Evapco is hereby increasing equipment pricing and freight allowances for all products manufactured in our North American factories. The price increases outlined below are effective March 19, 2018. The new/increased pricing will be active in our Spectrum selection software program on March 19. Old pricing

Marzo 5, 2018

Evapco had an exciting fourth quarter of 2017, and they used the 2018 AHR Expo to build upon that success. Evapco’s eco-Air Series of dry and adiabatic products provide flexibility in a wide range of capacities, footprints, motor types, and controls. “The world is changing,” said Jamie Facius, vice president, North America sales, Evapco. “Water is becoming more critical with shortages and drought conditions. We are positioning ourselves for that future with these dry and adiabatic units that can conserve a lot of water.” Read the full article in The News from ACHR.

Febrero 13, 2018

For evaporative cooling equipment like cooling towers, evaporative condensers or fluid coolers, water quality is essential for proper heat transfer and the healthy service life of the equipment. By association, that same water also is essential to the operation of the chillers, process equipment or building systems connected to the evaporative cooling equipment. Yet, some operators or building owners fail to recognize how the quality of the available makeup water and ongoing water treatment of the condenser water may impact equipment commissioning, operational water efficiency and lifespan of

Febrero 6, 2018

As aging facilities are tapped to accommodate expanded manufacturing and broader process applications, facility owners and managers are faced with vexing challenges. Primary among them is how to meet these demands within realistic budget parameters. Often, two of the largest budget items for facility managers is reducing energy use and water consumption. To magnify the challenge, some municipalities have set water-use restrictions for plants, creating an unexpected burden. Another facet of the challenge of doing more with less is the common problem of deteriorating mechanical infrastructure