Water Systems

How does the quality of my site’s makeup water impact water efficiency or influence materials of construction decisions?

Water originates from various sources and can vary significantly in quality. Makeup water contains invisible dissolved minerals and insoluble matter that can impact cooling efficiency and equipment service life. These substances include dirt, minerals, gases, and microbiological organisms that, if not properly treated, can accumulate and cause reductions in heat transfer efficiency, equipment service life or increased maintenance requirements.

As heat is rejected, the water evaporates as pure H2O leaving all the dissolved minerals behind to concentrate in the basin. As fresh water is added to replace evaporated water the dissolved minerals increase, a concept known as Cycles of Concentration (COC) or Cycling Up. The quality of the makeup water directly influences how high the cycles can safely be pushed which directly impacts water efficiency.

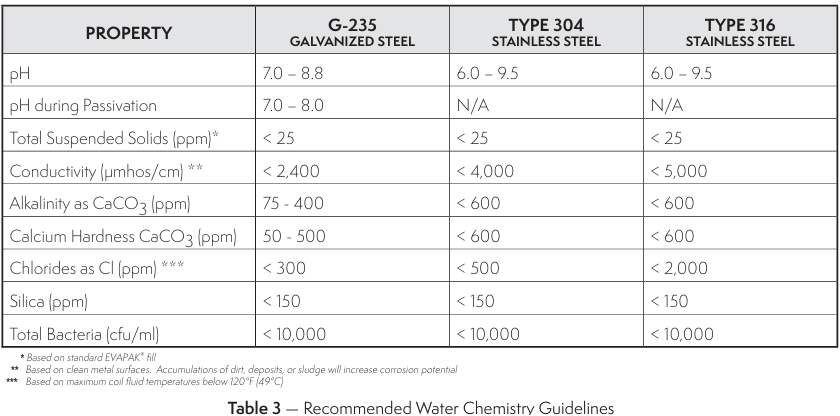

The quality of makeup water also plays a role in selecting appropriate materials of construction for your evaporative cooling equipment. Different materials have varying levels of corrosion and temperature resistance. Poor makeup water quality may necessitate the use of more corrosion resistant materials, such as 304 or 316 stainless steels. To aid in materials of construction selection, EVAPCO® has published water quality guidelines for open cooling towers, closed circuit coolers, and evaporative condensers that can be reviewed when making decisions on materials of construction:

Ultimately, understanding your makeup water quality will not only allow you to run your evaporative cooled system more efficiently by optimizing your cycles of concentration, but can also help extend your equipment’s service life by selecting appropriate materials of construction.

For more information, please contact your EVAPCO® Sales representative or [email protected].

How does the need for immediate heat load affect galvanized steel coils?

For decades, the evaporative cooling industry has relied on galvanized steel as a preferred material of construction due to its cost effectiveness and thermal performance.

Galvanized zinc provides corrosion protection for the underlying carbon steel. This zinc layer is both a protective layer and acts as a sacrificial anode when any damage or breaks occur. When properly passivated, new galvanized steel can provide significant corrosion resistance to extend the service life of the steel.

Given sufficient contact time in the atmosphere, the outer layer of newly galvanized steel will naturally passivate. This passive layer protects the zinc from a form of premature corrosion known as White Rust.

Many projects lack the time to allow this passivation process to occur naturally in the atmosphere before needing to start their evaporative cooling equipment under heat load. The need to operate the equipment wet increases the potential for White Rust formation. A field passivation is often required to create the surface reactions required to form a passive oxide layer on a new galvanized coil. Properly passivating new galvanized coils is more difficult when immediate heat load is required since elevated temperatures increase corrosion potential. Once white rust forms, it cannot be eliminated, which can create both short and long-term problems.

To improve real world passivation plans for evaporative cooling equipment commissioned with immediate heat load, EVAPCO® engineered an enhanced 2-step passivation solution to minimize white rust for galvanized equipment, Pass Protect ®.

To learn more about our Pass Protect ® offering and how to best commission your galvanized coil, please contact your local EVAPCO® sales representative or [email protected] .

What are the environmental, health & safety benefits of non-chemical or solid chemical water treatment programs for evaporative cooled systems?

EVAPCO® Water Systems offers advanced water treatment programs tailored to the specific needs of evaporative cooling systems, considering factors such as makeup water quality, unit type, and location. Two key solutions, Pulse~Pure® and Smart Shield®, are available for open cooling towers, closed circuit coolers, and evaporative condensers. These systems can be installed in the field or factory-mounted on coil products.

Pulse~Pure® is a non-chemical treatment system, while Smart Shield® uses solid chemistry. Both options provide significant benefits for environmental, health, and safety (EHS) compared to traditional liquid chemical treatment. By eliminating liquid chemicals, these systems reduce the costs and risks associated with shipping, handling, and storing liquid chemicals. Additionally, Pulse~Pure® systems may not require blowdown to a sanitary drain since no hazardous chemicals are added to the water.

These technologies also support environmental sustainability by lowering carbon footprints associated with the manufacturing and transportation of liquid chemicals. Solid and non-chemical treatments require less storage space and are easier to transport, making them ideal for challenging locations like rooftops application.

Both Pulse~Pure® and Smart Shield® come with the first year of startup and service included to help ensure optimal performance. For more information or to determine how to either Pulse~Pure® or Smart Shield® to your application, contact your local EVAPCO® Sales Representative or [email protected].

What risks, if any, are associated with using municipal reclaim, rainwater or softened water as makeup for my evaporative cooled system?

Questions regarding alternative makeup water sources for evaporative cooling have become more prevalent due to water scarcity and water usage concerns. These alternate sources of makeup water can be evaluated if the system is designed to provide consistent makeup water quality to the evaporatively cooled system. The following should be considered during the design please to minimize the potential for adverse impacts in terms of water efficiency or equipment service life.

Municipal reclaim water quality tends to be more variable compared to city or well water makeup. This variability in water quality can complicate the treatment program for the evaporative cooling system and often requires additional testing and control. Variations in ammonia, bacteria, chloride, fungi, organic and oxidant lo9ading, and phosphate should be planned for and controlled.

Rainwater harvesting may be appropriate to reduce potable water usage provided the system is designed to capture rainwater and blend it into the makeup in a controlled manner. In addition to storage tank capacity, these systems often require supplemental controls for consistent blending with potable water, filtration to reduce total suspended solids, metering, microbiological control and/or testing, and supplemental pumping. A professionally designed system is more complicated than simply dumping rainwater into the cooling system when it is available.

Water softeners are sometimes considered to reduce calcium and magnesium hardness to increase water efficiency (cycles of concentration). When considered, the water required to regenerate the softeners should be included in the preliminary analysis. Split-stream sodium zeolite softening may be a cost-effective way to reduce scaling potential. EVAPCO® does not recommend the use of 100% softened water for evaporative cooled systems. Equipment manufacturers, including EVAPCO, suggest that the cooling water have at least 30- to 50 ppm of calcium hardness (as CaCO3) to protect the cooling equipment. If split-stream sodium zeolite softeners are utilized, the treatment program should be cautious in terms of cycled alkalinity, chloride and pH in the cooling water.

While alternative water sources can enhance sustainability, their use does not offer a ‘free lunch’. A careful analysis should be undertaken to understand the requirements in terms of treatment feed and control, supplemental equipment, and additional testing associated with implementing the use of alternate water for makeup to evaporative cooled systems. The treatment program should detail how the system will mitigate additional corrosion, microbiological growth, operational variability and scaling potential associated with non-potable water use. Please refer to your manufacturers’ IOM for water quality guidelines and recommendations when considering alternative makeup water sources.

Without increasing my system’s cycles of concentration, how can I reduce blowdown and makeup water demand?

Water is required for energy efficient evaporative cooling commonly used in HVAC, refrigeration, and industrial process cooling systems. Water demand for these cooling systems can be significant. As the global water crisis grows, reducing water usage in these systems becomes more and more important. EVAPCO’s industry’s leading dry and adiabatic product lines offer significant water savings, but how can end users save water when evaporative cooling solutions are required or desired?

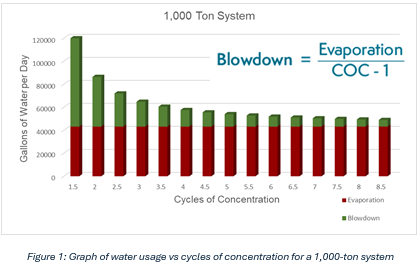

Water usage in [evaporative cooled systems] comes from two main sources: evaporation and blowdown. Evaporation is dictated by heat load and ambient conditions, neither of which can be reasonably changed.

Total water use and efficiency in an evaporative unit can be controlled by increasing, or decreasing, the system’s “cycles of concentration” (COC). The figure below shows the relationship between blowdown and COC, the lower the COC, the higher the blowdown and greater the water consumption.

Cycles of concentration is the concentration ratio of dissolved ions in the recirculated water compared to the same dissolved ions in the makeup water. For example, if your recirculating water contains 250ppm of Chlorides and the makeup water contains 50 ppm of Chlorides, your system is operating at 5 COC. Every evaporative cooling system has a maximum safe operating cycles of concentration based on the materials of construction and makeup water quality. To increase water efficiency beyond this maximum level, thus saving water, pretreatment technology can be applied. The most common pre-treatment approaches in the industry are water softeners and reverse osmosis (RO), which can both come with application risks. EVAPCO® developed Water Saver ® as an eco-friendly, pretreatment system to improve water efficiency in evaporative cooling equipment.

Water Saver® utilizes Capacitive Deionization (CDI) technology to remove charged ions from a water supply. This technology reduces the dissolved ion concentration from the makeup supply, thus lowering the makeup water conductivity allowing your recirculating water supply to operate at higher COC. In addition to reducing your overall water usage, this technology can significantly reduce treatment chemical use rates.

To learn more about your local water quality, optimizing system efficiencies and if Water Saver ® may contribute to significant water saving at your project, please contact your local EVAPCO representative or [email protected].