Shaping the Future of Engineering: EVAPCO and CCCTC Partner on Real-World 3D Modeling Project

Shaping the Future of Engineering: EVAPCO and CCCTC Partner on Real-World 3D Modeling Project

A Local Partnership with Lasting Impact

A shared commitment to education, innovation, and community development recently brought together two Carroll County institutions in an inspiring collaboration that bridged the gap between classroom learning and real-world application. EVAPCO, a global leader in heat transfer solutions and a proudly employee-owned company headquartered in Taneytown, Maryland, partnered with the Carroll County Career & Technology Center (CCCTC) to provide an exciting opportunity for students in the “Project Lead the Way” Engineering program.

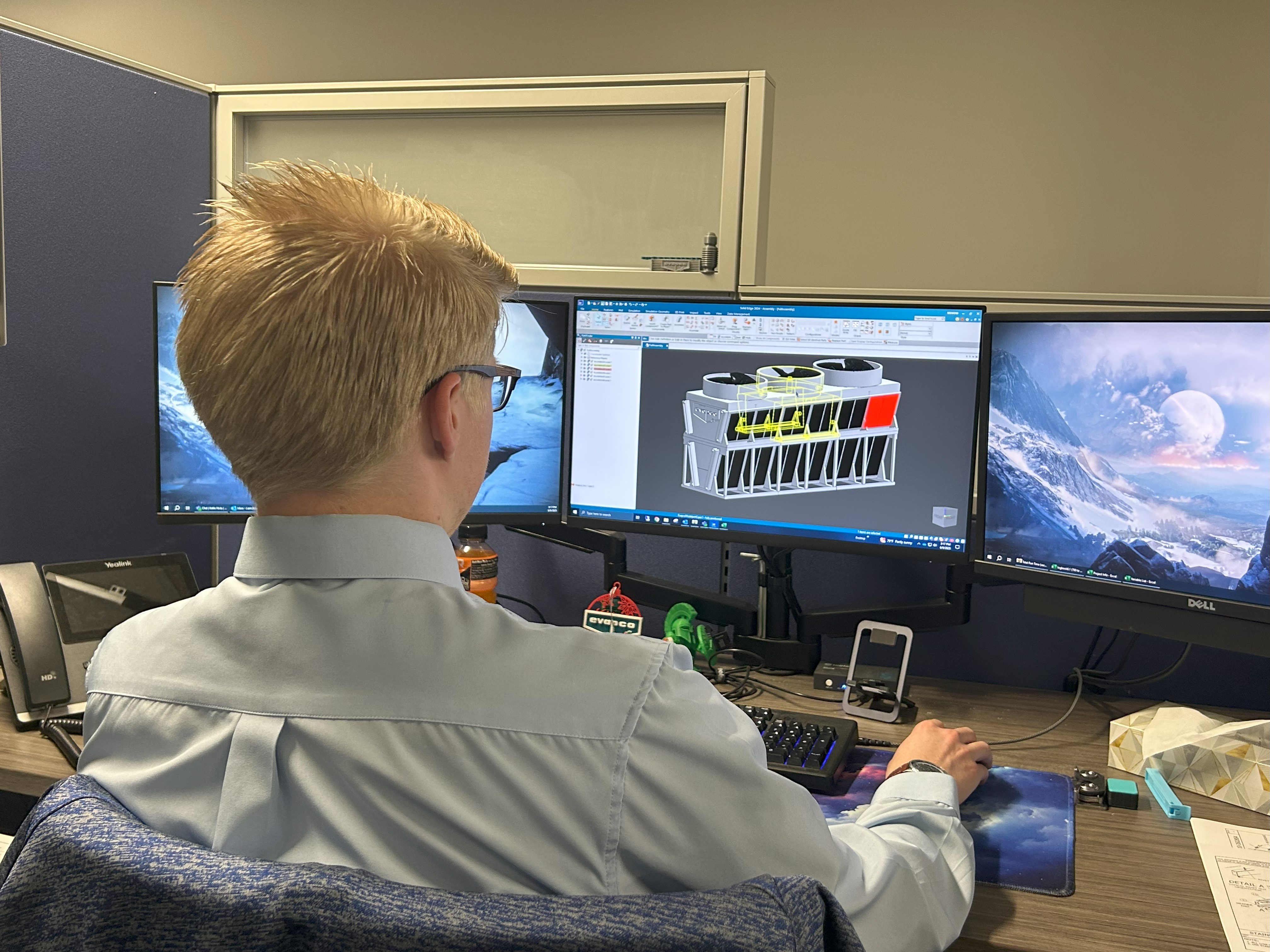

Under the leadership of Scott Tobias, Jen Sanders, and Kristina Talley, Engineering Instructors at CCCTC, senior Jackson Rilley and junior Connor Tracy were challenged with a unique assignment to design a fully detailed 3D model of an EVAPCO eco-Air® Series Double Stack Dry Cooler. This industrial cooling unit plays a crucial role in applications where water conservation and efficiency are paramount, such as data centers, power plants, and manufacturing facilities. The project offered Rilley and Tracy the chance to take on a real-world engineering challenge, applying their technical skills in 3D drafting, modeling, and design while collaborating with a professional organization.

“Working on a project like this was a super cool opportunity because, in my class so far, I’ve usually been given an assignment on a piece of paper with a strict rubric that determines my grade. But this project gave me a taste of real-world design applications, project deadlines, meeting experiences, and having professional conversations. Not only that, but seeing our design go from a little model on the computer screen to this massive physical model was mind-blowing and has definitely grown my passion for this field,” said Connor Tracy.

“Getting to design something that will be 3D printed and used in the real world was a great experience,” added Jackson Rilley. “It made everything we’ve been learning in class feel more meaningful—and it showed me what I might want to do in the future.”

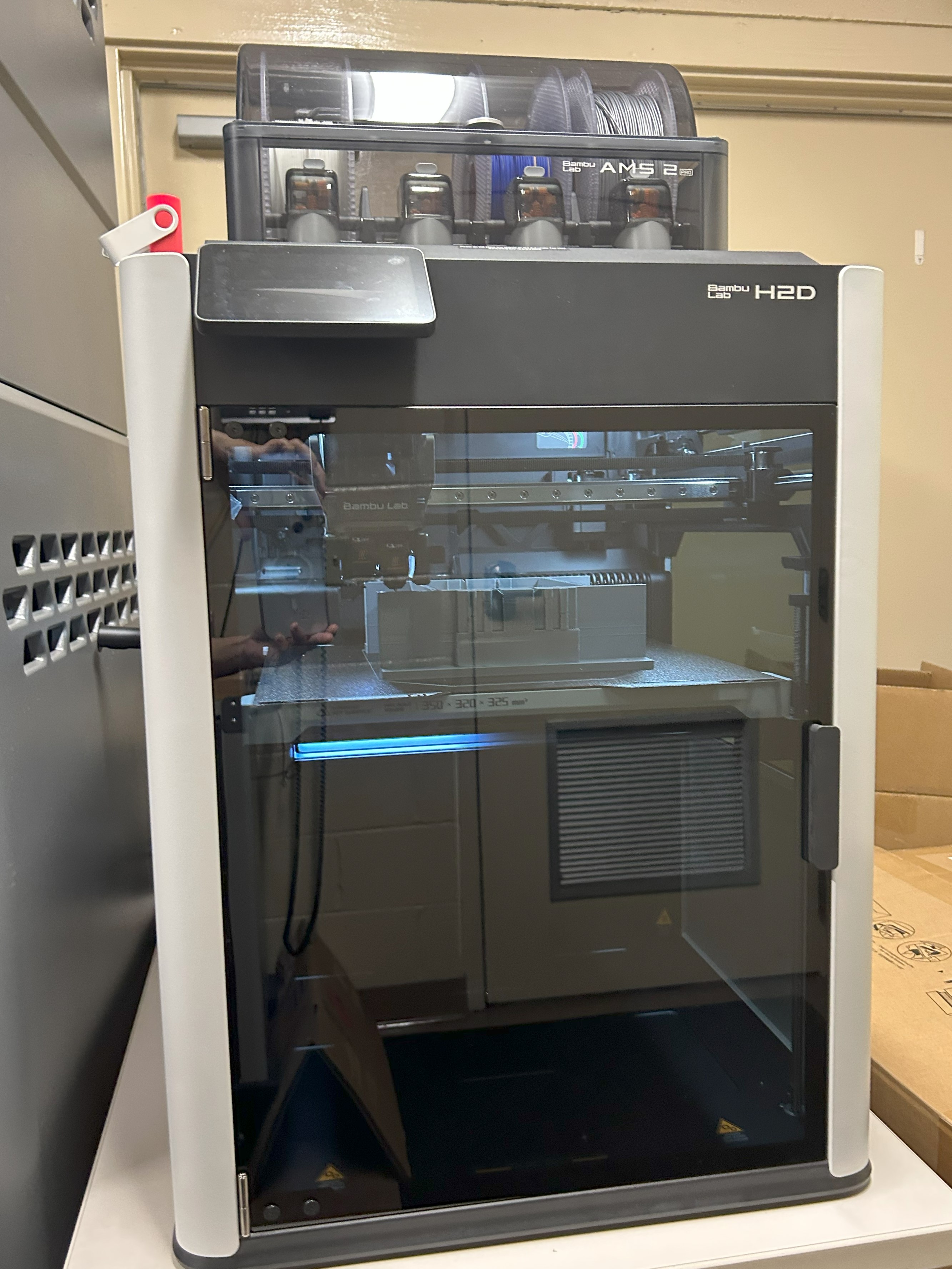

Over a short timeframe, the students worked diligently to develop an accurate and functional .STL file of the cooler for 3D printing. Their work involved interpreting complex dimensions, refining geometric features, and simulating real product conditions. Upon completion, the digital model was sent to EVAPCO headquarters, where it was brought to life via 3D printing by Liam Bates, Senior Drafter in Product Development.

A Full-Circle Moment

What makes this collaboration especially meaningful is the full-circle connection it represents. Liam Bates is a graduate of CCCTC’s Applied Mechanical Engineering program. Having walked the same hallways and studied under the same foundational program, Liam’s involvement in completing the students’ work brought a powerful layer of mentorship and continuity to the project. It is a testament to how technical education programs can shape careers and how alumni can return to elevate the next generation.

“It was really rewarding to support Jackson and Connor with this project—especially knowing I was once in their shoes,” said Bates. “Seeing the skills they’ve developed at CCCTC come full circle and apply to a real-world product is proof of how powerful technical education can be.”

“Watching this project come together was incredible,” said Scott Tobias. “Jackson and Connor took real ownership of their work, and the fact that it was printed and validated by a CCCTC graduate now working in the field made it even more special. It’s the kind of collaboration that motivates students to see what’s possible.”

EVAPCO has long recognized the value of investing in local talent and has an ongoing relationship with CCCTC through career fairs, educational outreach, and hiring efforts. Several former CCCTC students have joined the company in full-time roles, bringing their skills and work ethic to an organization that values technical precision and innovation.

As an employee-owned company, EVAPCO has a unique culture that rewards dedication, encourages professional growth, and supports its team from the ground up, which aligns well with the mission of CCCTC.

“This partnership is about more than just a school project,” said Stephen Engelhardt, Design Group Manager of Industrial Refrigeration Product Development at EVAPCO. “It’s about building a pipeline of skilled, passionate young professionals who are ready to make an impact. We’ve seen firsthand how CCCTC students bring value to our organization, and we’re proud to continue supporting programs that give them meaningful opportunities.”

A Model with a Purpose

EVAPCO plans to use the student-designed 3D model as a versatile marketing and educational tool across a range of settings. From career fairs and community expos to national industry conferences, the printed model will serve as a tangible representation of the company’s innovative product line and its commitment to engineering excellence. It will also be showcased at EVAPCO’s global headquarters as a hands-on display for visitors, customers, and prospective employees, illustrating not only the technical features of the eco-Air® Series Double Stack Dry Cooler but also the value of local collaboration and workforce development.

For Jackson Rilley and Connor Tracy, this experience was more than just an academic assignment. It was a preview of what a career in engineering and design can look like. They left the project with a greater understanding of real-world expectations, improved technical skills, and the confidence that comes from seeing their work applied in a professional setting.

Looking Ahead

As technology and manufacturing continue to evolve, partnerships like this one between EVAPCO and CCCTC serve as powerful models for how industry and education can collaborate to benefit students, employers, and the community at large. The story of Rilley, Tracy, Tobias, and Bates is a reminder that great things happen when we invest in local talent, and that the future of innovation starts right here in our own backyard.