News

novembre 10, 2023

U.S.-based OEM Evapco has launched VersaSplit, a new condensing unit that the company deems the “world’s first” packaged low-charge ammonia (R717) mega-split refrigeration system, with up to six remote direct expansion (DX) evaporators operating at different temperatures. VersaSplit, with up to 165TR (580kW) refrigeration capacity, doubles the capacity of Evapco’s roof-mounted Penthouse 70TR (246kW) unit and brings versatility to the industrial market, said Kurt Liebendorfer, Evapco Vice-President, in an exclusive interview with Marc Chasserot, Founder and Owner of ATMOsphere, publisher of

octobre 26, 2023

We are thrilled to unveil "EVAPCO for Life," the electrifying theme song with lyrics penned by Devon Nickoles. This original production honors the essence and spirit of EVAPCO, and we're proud to showcase the incredible talent within our team. Join us in this harmonious journey of dedication and commitment to excellence. Click here to watch the performance!

octobre 23, 2023

Incorporating HVAC into a grocery store's CO2 (R744) refrigeration system introduces parallel compression to stabilize medium-temperature (MT) compressor demand during high ambient temperatures. This finding comes from a case study conducted in Montreal by the Canadian-based OEM EVAPCO LMP. The details of the integrated system's installation and operation, which also featured heat and gray water reclaim, were presented at the FMI- The Food Industry Association Energy and Store Development Conference. The presentation was given by Francois Aucoin, Director of Engineering at EVAPCO LMP, and

août 3, 2023

Refrigeration and Air Conditioning Africa (RACA) Journal recently published an article written by, Eamonn Ryan, titled "The Strangest Batteries: An Ice Maker that Chills a Building." The article explores an innovative ice maker system that stores energy as ice, providing sustainable cooling for large buildings. This groundbreaking technology includes EVAPCO's thermal ice storage, revolutionizing the cooling industry and reducing environmental impact. Click here to read the full article.

juillet 14, 2023

Engineered Systems Magazine, a leading publication in the field of engineering and building systems, proudly presents an in-depth article by Tyler Lee, a renowned expert from Chesapeake Systems, shedding light on the prevention of critical failures of evaporative cooling equipment. The article, titled "How to Prevent Critical Failures of Evaporative Cooling Equipment," delves into the vital importance of maintaining efficient cooling systems in industrial and commercial settings. Tyler Lee's extensive experience and expertise provide readers with valuable insights and practical solutions to

juillet 10, 2023

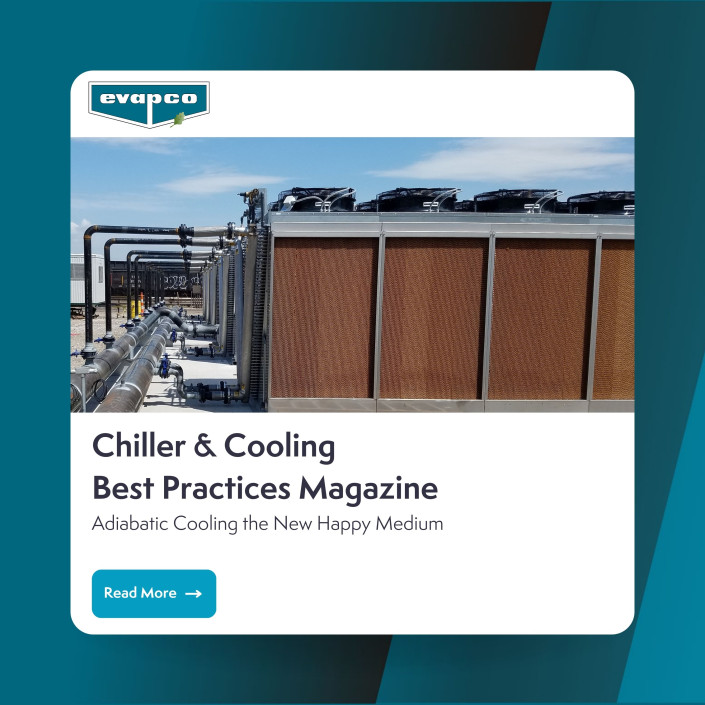

The need for cooling capacity is increasing globally. An expanding population and an evergrowing dependence on data increases the need for process cooling, centralized space cooling, and data center cooling. Meanwhile, in many places, water scarcity is a massive issue. In conventional, industrial cooling applications, the use of water for heat rejection is critical. Cooling towers and most evaporative fluid coolers depend heavily on water to reject waste heat to the atmosphere. Taking blowdown and drift losses into account, evaporative cooling systems use approximately three GPM per 100 tons

juin 26, 2023

U.S.-based OEM Evapco has installed its first low-charge ammonia (R717) split refrigeration systems at a cold storage facility in Reno, Nevada. The project was completed in partnership with specialist contractor Ti Cold, which views the technology as “revolutionary” for the industry. The new Tahoe-Reno Industrial Center’s five cold rooms and loading dock are cooled by 10 Evapcold LCR-S Split Systems, which provide a total of 676TR (2.4MW) of cooling capacity with just 4,664lbs (2,116kg) of ammonia. Each system consists of a rooftop adiabatic air-cooled condensing unit and two ceiling-mounted

juin 15, 2023

Data centers rely heavily on the capability and optimal performance of heat rejection equipment being utilized to function efficiently. When conserving water is a primary goal, careful attention must be given to the heat rejection equipment being specified. Data center cooling applications can be served by either an open-loop cooling tower or a closed-circuit cooler. The requirements of the application, location of the facility, local utility costs, water availability, and environmental considerations are the primary factors when choosing between the two. Click here to read the full article.

mai 5, 2023

A recent Los Angeles Times article has showcased EVAPCO's state-of-the-art chillers, which will be utilized in the cooling systems of the innovative all-electric hospital set to open in 2025. The project, led by UCI Health, aims to create a cutting-edge healthcare facility that focuses on energy efficiency, sustainability, and improved patient care. The article highlights the hospital's ambitious goals to reduce its carbon footprint and achieve net-zero carbon emissions, while providing exceptional healthcare services. A critical component of this endeavor is the implementation of advanced

mai 5, 2023

We are thrilled to announce that our very own Troy Reineck, known as "EVAPCO's Professor," was one of the industry experts invited to share their insights on evaporative cooling in a comprehensive article published by ACHR News. The article emphasizes the growing significance of energy-efficient cooling solutions and explores the critical role evaporative cooling plays in achieving sustainability objectives. Several experts, including Troy Reineck, were asked to provide their expertise on the development, implementation, and benefits of evaporative cooling systems. During his interview