The new 14’ x 26’ PHW Parallel Hybrid Closed Circuit Cooler was designed to maximize capacity and optimize energy efficiency in EVAPCO’s single largest closed circuit cooler cell available. It offers more capacity and layout flexibility than ever before. The PHW offers high tonnage capability specifically for Industrial Plants, Data Centers, and Large HVAC applications, where the end user requires the fewest number of units, connections, and fans.

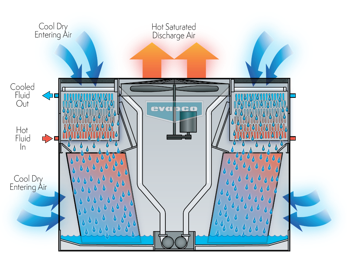

This mechanical induced draft, crossflow Closed Circuit Cooler utilizes EVAPCO’s Crosscool™ Internal Tube Enhancement with the patented elliptical tube Sensi-Coil® Technology and includes EVAPCO’s New and Improved XPak™ Crossflow Fill, on both the 14’ x 26’ and the 12’ x 24’ PHW.

The PHW has undergone extensive thermal testing to ensure each closed-circuit cooler will perform as specified. As with all EVAPCO products, each PHW closed circuit cooler is supplied with a written Thermal Performance Guarantee.

The PHW offers CTI Certified Performance.