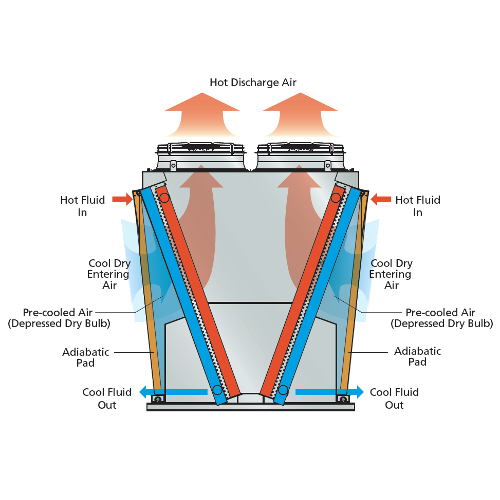

Adiabatic Pre-cooling System

- Wetted pads can be utilized for pre-cooling entering air, resulting in greater energy savings, and increased capacity, with minimal water use

- Great for high ambient dry bulb climates or high temperature applications

- Once-through design

- No water treatment required

- No cold water basin or pump

- No drift

Reduced or Eliminated Water Consumption

Compared to traditional evaporative systems, the eco-Air series will either eliminate or dramatically reduce water consumption. Adiabatic models only use water when the ambient conditions and load require it. Reducing water consumption also reduces the ongoing expenses related with the cooling equipment such as purchasing, treating, and disposing of water. When the eco-Air adiabatic models are used in conjunction with the EVAPCO controls package, water conservation is maximized based on proprietary PLC logic.

Reduced Maintenance

Scaling, corrosion, and water born bacteria concerns are minimized or eliminated with dry and adiabatic cooling equipment. The eco-Air Series reduces the maintenance traditionally associated with fully evaporative systems. The eco-Air adiabatic condenser is designed as a once through system, meaning it has no pump and no basin to hold water, which further reduces the time required for maintenance. Additionally, the adiabatic pads filter the air before reaching the coil, limiting the exposure of dirt and debris to the tube and fin heat transfer surface. Both NEMA and EC motor options require zero routine maintenance. There are no bearings to grease, belts to adjust, or fans to pitch and balance.

Advanced Motor Technology

Available with Electronically Commutated (EC) or NEMA fan motor designs.

The motors on the eco-Air series are pre-wired at the factory to UL standards, reducing costs associated with field wiring. As standard, all units are wired to a common terminal box. Adding the EVAPCO controls package allows for both single point power supply and complete capacity control.

NEMA

- Premium efficient direct drive

- Zero maintenance sealed bearings

- VFD ready

- Severe Duty

EC

EC motors are the latest development in energy savings and speed control.

The high efficiency wing tip fans operate up to 3 dB less than conventional blade fans with improved part speed energy consumption.

- Zero maintenance

- Integrated speed control

Advanced Construction

Superior Stainless Steel Technology

- Constructed with high-grade Type 304L stainless steel tubing as standard

- Meets ASME B31.5 refrigerant piping code

- Available in 5/8-inch OD

Coil Design

Through the use of computational fluid dynamics (CFD) modeling software, finite element heat transfer analysis, and proprietary coil performance calculation methods, EVAPCO engineers have identified significant design elements to improve the finned coil performance. The extensive computer modeling has been refined and verified through coil performance evaluation in EVAPCO's state of the art research laboratories.

Coil Return Bend Covers

Protects the coil return bends during handling and operation

Large Inspection Panel

Easily removable for interior inspection and access to coils and fan motors

Easy Rigging

All units are designed to ship and install as a single piece

Fork Lift Channels

Standard on all units up to 27 feet in length